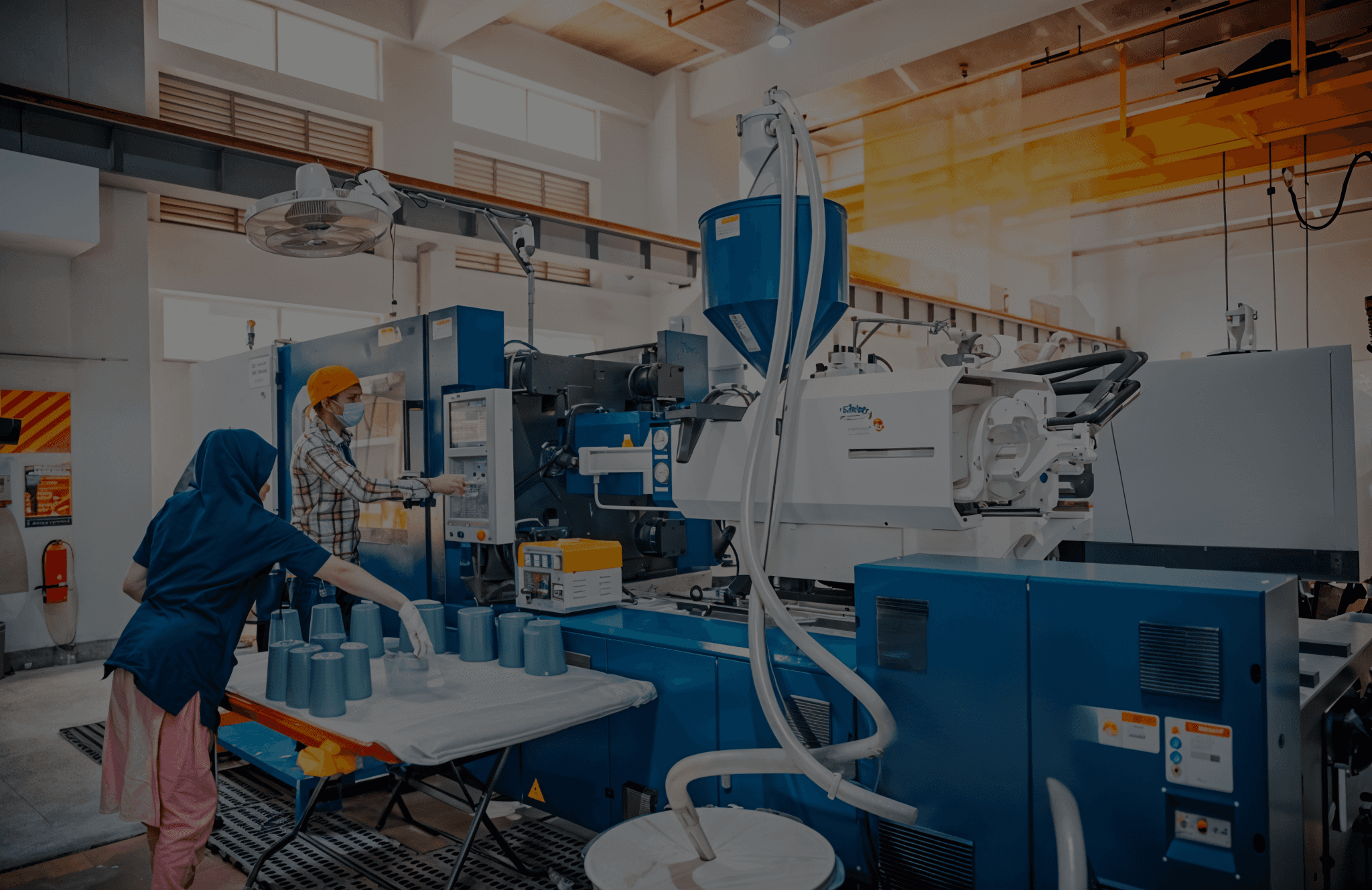

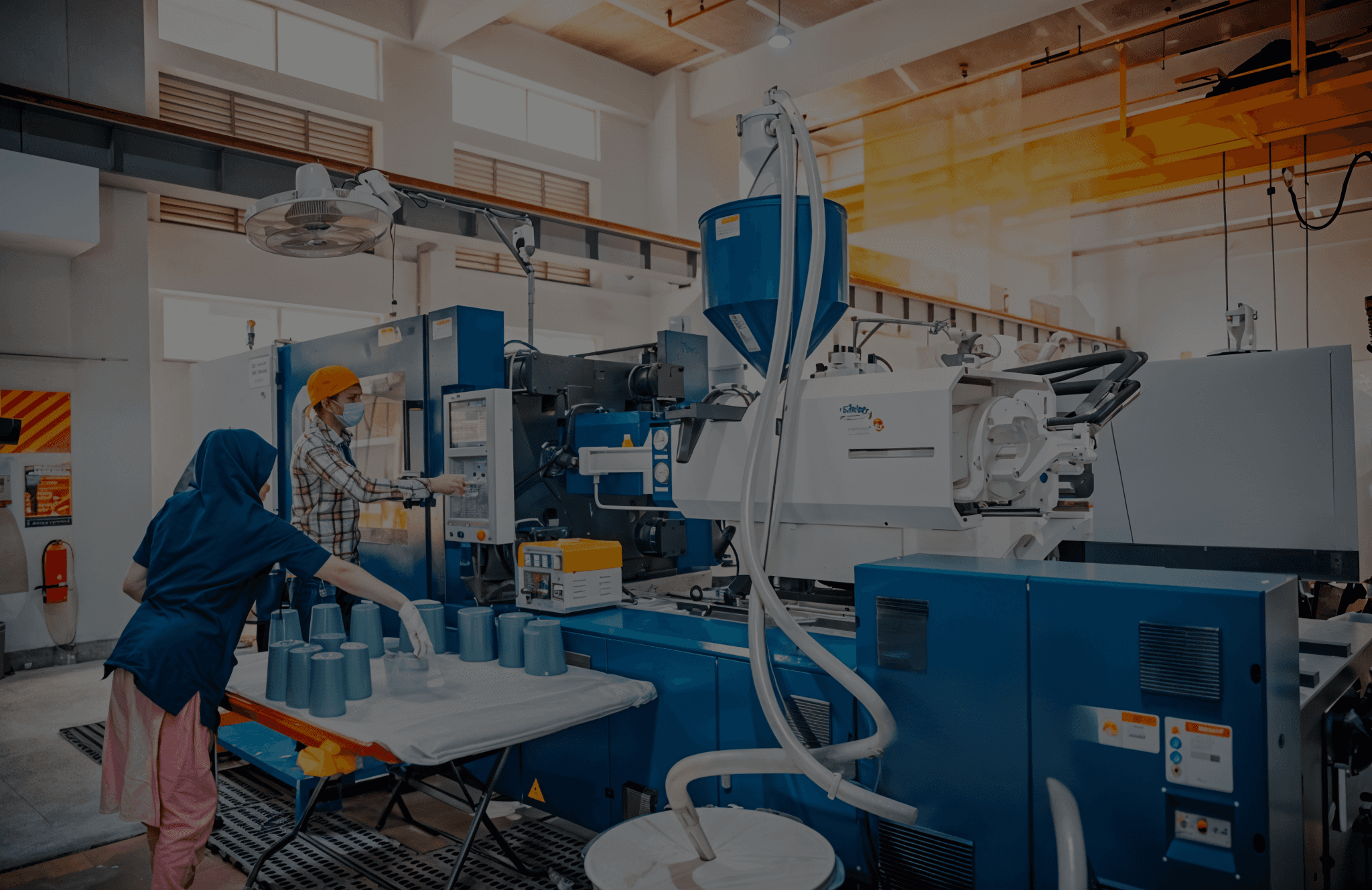

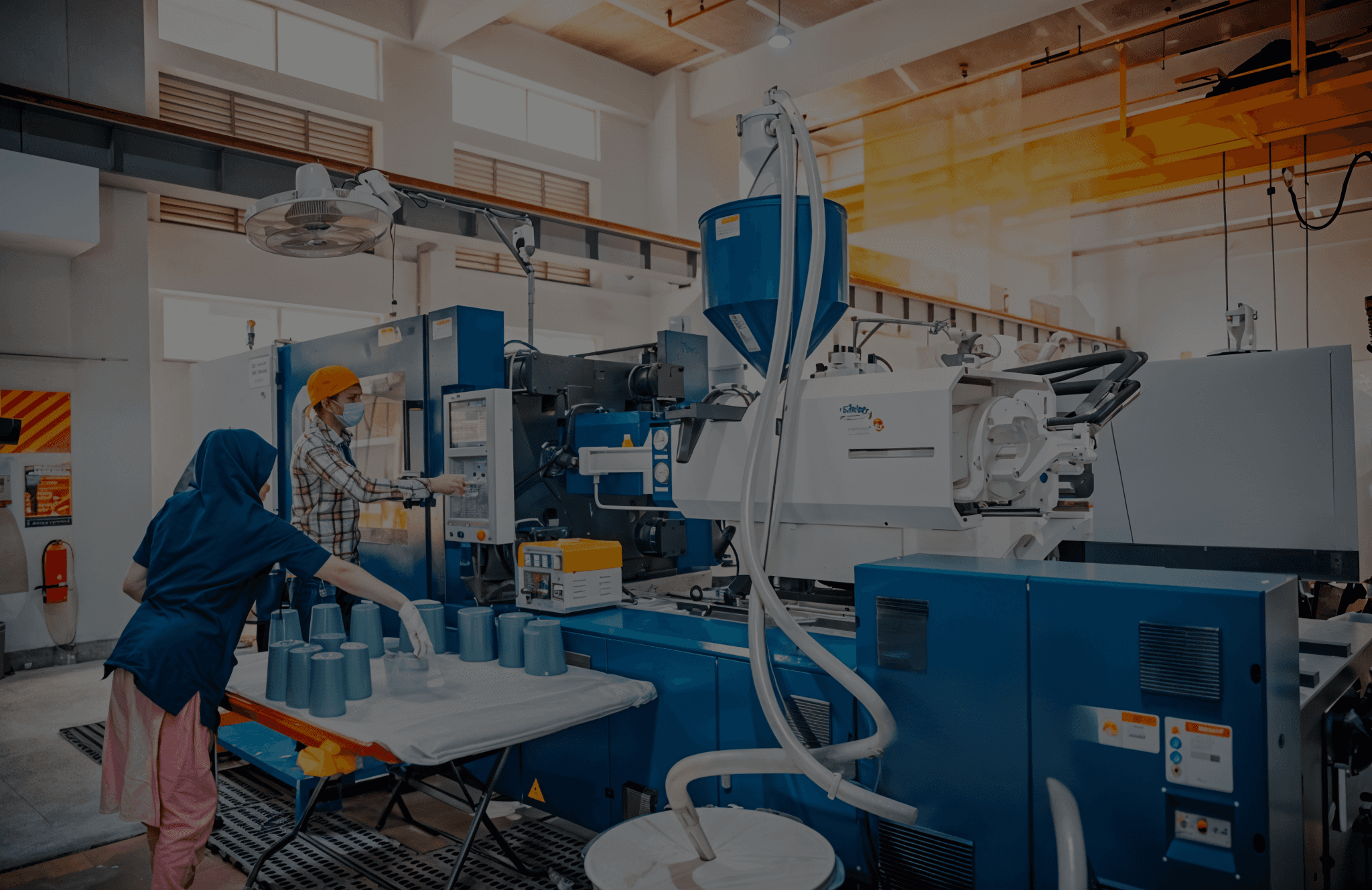

Designed to meet your unique specifications

We create high-quality, customized plastic components through Injection, Extrusion and Blow Molding Processes.

Designed to meet your unique specifications

We create high-quality, customized plastic components through Injection, Extrusion and Blow Molding Processes.

Designed to meet your unique specifications

We create high-quality, customized plastic components through Injection, Extrusion and Blow Molding Processes.

Benefits of Custom Injection Molding

Benefits of Custom Injection Molding

Benefits of Custom Injection Molding

Your Vision, Expertly Molded

Your Vision, Expertly Molded

Your Vision, Expertly Molded

Precision and Accuracy

Precision and Accuracy

Precision and Accuracy

Achieve tight tolerances and complex geometries

Achieve tight tolerances and complex geometries

Achieve tight tolerances and complex geometries

Versatility

Versatility

Versatility

Suitable for a wide range of materials and applications.

Suitable for a wide range of materials and applications.

Suitable for a wide range of materials and applications.

Reliability

Reliability

Reliability

Easily scale from prototype to full production

Easily scale from prototype to full production

Easily scale from prototype to full production

Our Process

Our Process

Our Process

From Concept to Delivery

From Concept to Delivery

From Concept to Delivery

1

Planning

Planning

Planning

Understand your needs and project requirements.

Understand your needs and project requirements.

Understand your needs and project requirements.

2

Installing

Installing

Installing

Set up and configure molding machinery and tools to begin the process.

3

Production

Production

Production

Manufacture high-quality, customized plastic components with precision.

4

Analyzing

Analyzing

Analyzing

Evaluate and inspect the molded parts to ensure they meet all specifications.

5

Semi-Packing

Semi-Packing

Semi-Packing

Secure the molded components and prepare them for final assembly.

6

Send for Assembly

Send for Assembly

Send for Assembly

Deliver components for final assembly and completion of the product.

Frequently Asked Questions

Frequently Asked Questions

What materials can you use for custom injection molding?

What materials can you use for custom injection molding?

What materials can you use for custom injection molding?

How long does it take to develop a custom mold?

How long does it take to develop a custom mold?

How long does it take to develop a custom mold?

What is the minimum order quantity for custom injection molding?

What is the minimum order quantity for custom injection molding?

What is the minimum order quantity for custom injection molding?

Can you assist with design and engineering for custom molds?

Can you assist with design and engineering for custom molds?

Can you assist with design and engineering for custom molds?

How do you ensure the quality of custom molded parts?

How do you ensure the quality of custom molded parts?

How do you ensure the quality of custom molded parts?

Ready to take your project to the next level?

Ready to take your project to the next level?

Ready to take your project to the next level?

Contact us today to learn how Aroson Plastics can provide you with top-tier plastic manufacturing solutions through our advanced molding processes.

Contact us today to learn how Aroson Plastics can provide you with top-tier plastic manufacturing solutions through our advanced molding processes.

Contact us today to learn how Aroson Plastics can provide you with top-tier plastic manufacturing solutions through our advanced molding processes.

Copyright © 2024 | Aroson Plastics | All Rights Reserved

Copyright © 2024 | Aroson Plastics | All Rights Reserved

Copyright © 2024 | Aroson Plastics | All Rights Reserved